The cooking process is vital to the pretreatment of some oilseeds. It consists of heating the seed and reducing the moisture content.

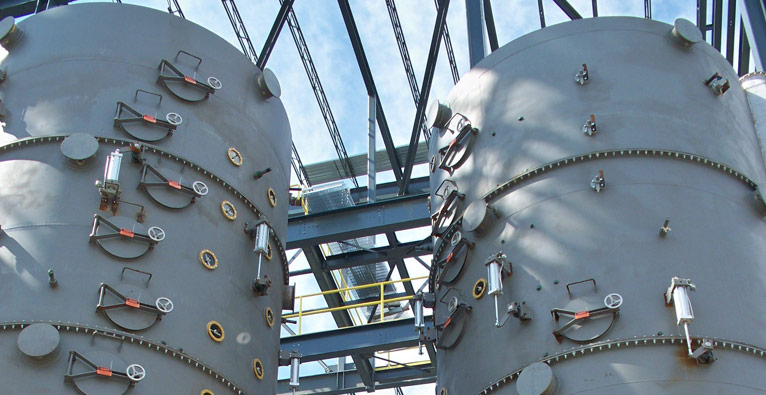

The cooking operation is usually carried out in a stacked cooker, a vertical design where the seed moves down through steam-heated trays, each with its own stirrer system mounted on a common vertical shaft. The diameter of the stack and number of trays depends on the capacity required and the seed being processed.

A small quantity of direct steam can be injected at the top trays to heat the seed and improve the rupturing of the oil-bearing cells. After that, the steam coming from the vaporization of the seed moisture is sufficient. The stirrers agitate the material to ensure uniform cooking and provide a means for transferring meal through successive compartments.

- Simple operation provides flexibility for multiple seed varieties

- Seed levels and overall residence times are easily adjustable

- Superior tray and shell design provide for years of trouble-free service

- The cooker may be either top-fill or bottom-fill design

- Shell material may be stainless steel for improved corrosion resistance

- Level control is accomplished by means of simple chutes, mechanical gates or rotary valves

- Mechanical gates may include actuators and positioners